The orthogonal selectivity offered by the 3 different stationary phases allows a suitable starting point to be made with scope for a highly qualitative method design. Figure 4 shows the separation of a complex mixture of analytes using a C18, Diphenyl and PFP core-shell particle. We need to incorporate selectivity into our equation for both core-shell and UHPLC: this variable will allow optimum resolution to be found for the wide diversity of compounds types encountered in the pharmaceutical pipeline. Therefore the one variable that does become most important to this high throughput chromatography is that of selectivity (Figure 3). As we improve N through reduced peak width we can go faster and faster with our analysis, however at a certain point we will start to run out of time for our peaks to elute (no matter how narrow they are). This leads me onto peak capacity (unit resolution, peaks per unit time), one of the variables that will change heavily in the move from HPLC to UHPLC or core-shell. If I have a core-shell particle column then I need to compare lifetime with another core-shell, not with my previous HPLC column and I need to use number of samples as the measure, not calendar days. So we have to compare apples with apples. If the UHPLC column did last 90 days that would mean by the same logic that we would have analysed (90/15 x 2000) 12,000 samples instead on the same column. Why should it? Column lifetime is more related to sample throughput than to pure ‘calendar months’.

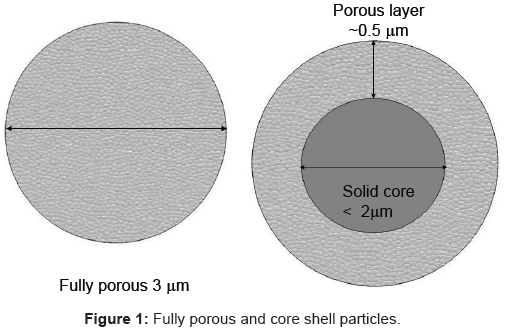

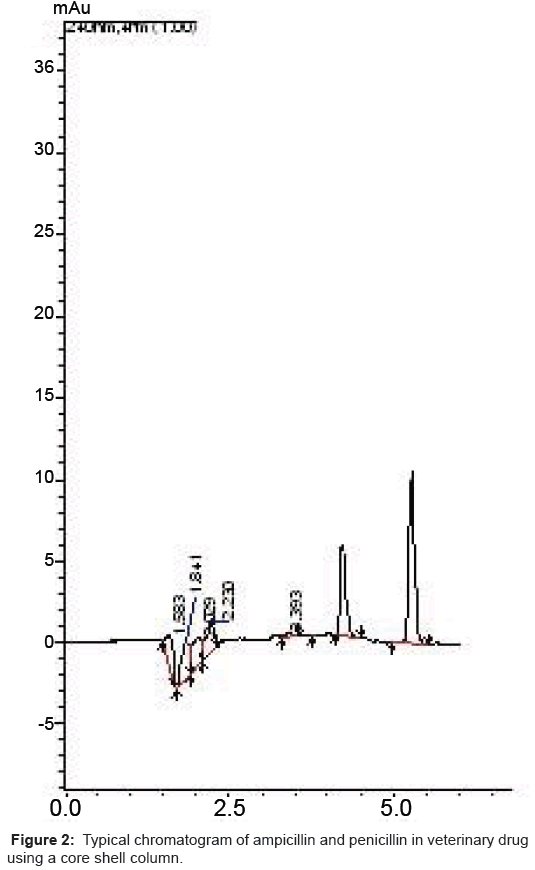

Yet the number of times I have a customer say that the UHPLC column now doesn’t last 90days like their HPLC column did is strange. However now if we have a UHPLC or core-shell column and our assay takes 10minutes with a 1 minute equilibration, then our 2000 samples take approximately 15days. So approximately one column per assay per quarter. With a 60minute run time and 5minute equilibration time, 2000 samples would take us approximately 90days working constantly 24hrs a day, 7 day a week. In HPLC we would expect a lifetime of 1000-2000 injections to be reasonable, sometimes much longer. Lifetime is also an interesting issue from a manufacturers and end-users point of view. As an example, at Fortis Technologies we pack our 1.7µm particles at >1400bar (approx.20,000 psi pressure) ensuring that the packed bed is stable well above the usual working limits of the commercial UHPLC systems on the lab bench. Obviously characteristics such as backpressure then have a big impact on the lifetime of columns, along with the linear velocities that can be achieved (Figure 2).ĭoes backpressure work totally against UHPLC particles, not really, if the manufacturer has done a good job then the sub 2µm particle should withstand the elevated pressures. As with all technology there will be differing manufacture processes in the production of these core-shells and therefore a potentially wide range of physical characteristics, resulting in a range of pressures, hydrophobicities and peak shapes (Figure 1). Current theory has the efficiency generated by these particles arising largely from the mono disperse nature of the solid core coupled with the reduced void volume of the column and to a lesser extent from the reduced mass transfer that takes place during the separation. Now in the last couple of years a ‘new’ technology core-shell (fused-core, solid-core, superficially porous particles, SPP, call it what you will) has now peaked everybody’s interest! Again I highlight the word ‘new’ since these types of particles were actually first discussed and commercialised back in the 1970’s by Zorbax technologies.Ĭore-shell technology uses a solid silica core and a porous outer silica shell to provide the same high efficiency separations as the sub 2µm UHPLC particles, but with potentially lower backpressure.

0 kommentar(er)

0 kommentar(er)